Microplastics (MPs), referring to plastic particles with a diameter less than 5mm, have been detected as a new type of pollutant in aquatic environments, terrestrial environments, and the atmosphere worldwide in recent years, including Antarctica. They have complex physical and chemical properties that can alter their migration rate or toxicity to organisms. Therefore, rapid and efficient detection of microplastics is crucial for understanding their toxicology and ecological impact. The common pretreatment methods for microplastics in soil are sieving, sorting, removing organic matter and other soil components, extraction, and concentration, which are relatively complicated operations.

This method uses pressurized fluid extraction to extract polystyrene (PS) from the soil. Its polymer main chain is a C-C bond, the side group is a benzene ring, and the intermolecular cross-linking is mainly the chemical bond of the C-C bond and the conjugated benzene ring of the side group. Using a high-temperature and high-pressure environment, the cross-linking bonds of the plastic particles are destroyed, reducing the molecular weight of the polymer to small molecules, and using an appropriate solvent to dissolve the small molecules. The extract is concentrated to 0.5mL by nitrogen blowing, an internal standard is added, and it is diluted to 1mL with dichloromethane, and analyzed on a pyrolysis-gas chromatography-time of flight mass spectrometer (PY-GC-TOF-MS).

This method is convenient to operate, has high extraction and concentration efficiency, and good recovery rate, and can serve as an effective solution for the pretreatment and analysis of microplastics in soil.

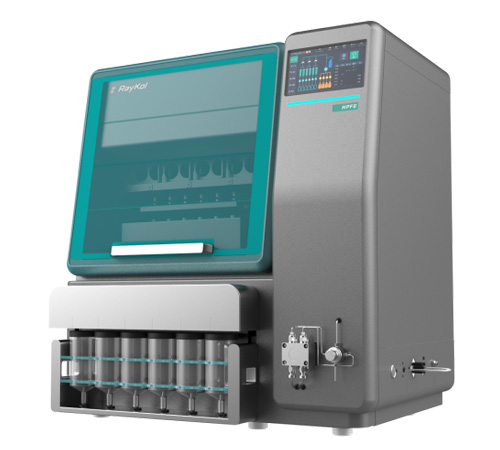

Instruments | Raykol HPFE Series High Throughput Pressurized Fluid Extraction Instrument |

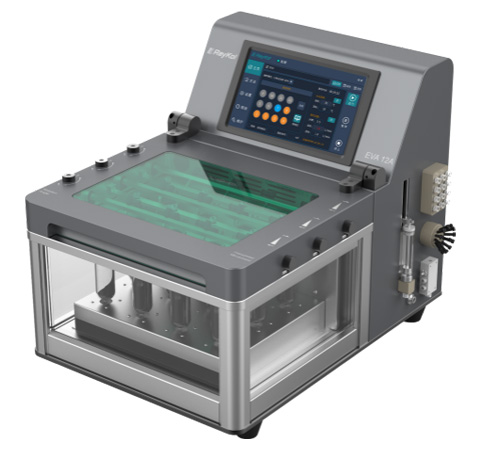

Raykol Auto EVA 12 Automatic Quantitative Parallel Concentrator | |

Reagents | Dichloromethane: HPLC grade |

Pyrolyzer: Frontier EGA/PY3030D from Japan | |

Gas Chromatography-Time of Flight Mass Spectrometer: DANI MASTER GC/TOF-MS from Italy |

>Weighing

Weigh 10g of environmental soil sample, add an appropriate amount of diatomaceous earth and mix evenly. In a 34mL extraction kettle, first fill in 2 spoons of quartz sand, then fill in the mixed soil sample, and finally fill in 2 spoons of quartz sand.

>Extraction

After filling the other extraction kettles, place them in the HPFE for extraction.

Experimental conditions: preheating at 150℃, extraction temperature at 180℃, pressure at 13.6MPa, static extraction time at 300s, and purging for 90s. Extraction solvent: dichloromethane. The extraction cycle is repeated twice.

>Concentration

The extract is placed in the Auto EVA 12 and automatically concentrated to 0.5mL at 40℃, internal standard is added, and the volume is made up to 1mL with dichloromethane.

>Detection

Detection is carried out using a pyrolysis-gas chromatography-time of flight mass spectrometer.

HPFE Series High Throughput Pressurized Fluid Extractor

Auto EVA 12 Automatic Quantitative Parallel Concentrator

This scheme uses the Raykol HPFE high-throughput pressurized fluid extractor to extract polystyrene microplastics from soil, simplifying the conventional pretreatment steps and greatly improving work efficiency. The extract is concentrated by the Auto EVA 12 automatic quantitative parallel concentrator, which can automatically set the volume to 0.5mL or 1mL, eliminating the need for personnel to watch over. The entire extraction and concentration process can be automated, with good experimental stability, avoiding the problems caused by large manual operation errors and poor parallelism.