Benzopyrene (a) pyrene, is a fused ring aromatic hydrocarbon containing benzene rings, abbreviated as BaP. Benzopyrene (a) pyrene is the most main environmental and food pollutant among more than200 types of polycyclic aromatic hydrocarbons discovered, widely polluted and in large quantities, with strong carcinogenicity. During the processes of smoking, baking, and frying food, fats, cholesterol, proteins, and carbohydrates undergo thermal cracking reactions at high temperatures, followed by cyclization and polymerization reactions to form polycyclic aromatic hydrocarbon substances including benzopyrene (a) pyrene. Especially when food becomes charred during smoking and baking, the production of benzopyrene (a) pyrene increases by 10 to 20 times compared to ordinary food. Therefore, it is of great significance to detect benzopyrene (a) pyrene in food.

This article refers to GB 5009.27-2016 "National Food Safety Standard for the Determination of Benzopyrene (a) pyrene in Food" for the pretreatment method. Using the automatic sample purification-concentration apparatusSPEVA 08N from RayKol Group, achieving one-key automatic purification, elution, and concentration of oil samples for benzopyrene (a) pyrene, acetonitrile reconstitution, high-performance liquid chromatography detection, and external standard method quantification. At the spiked level of1.0μg/kg, the recovery rate of benzopyrene (a) pyrene is between 88%-93% , with an RSD value of less than 5%, indicating that this method can meet the efficient and accurate determination requirements of benzopyrene (a) pyrene residues in oil samples.

RayKol Group SPEVA 08N Automatic Sample Purification-Concentration Apparatus

Speva Automated Spe & Evaporation System

Agilent 1260 Infinity II High Performance Liquid Chromatograph

Benzopyrene (a) pyrene molecularly imprinted column: 500mg/6mL

n-Hexane (Chromatographic grade)

Dichloromethane (Chromatographic grade)

Acetonitrile (Chromatographic grade)

Weigh 1g of oil sample into a glass test tube, add 10ml of n-hexane, vortex and dissolve for 0.5min, allow all the sample to pass through the column.

Successively use 15ml of dichloromethane and10ml of n-hexane to activate the column, pass all the solution to be purified through the column, wash the column with 6ml of n-hexane, and discard the outflow. Finally, elute with 5ml of dichloromethane, evaporate the eluent to near dryness with nitrogen at40℃, reconstitute with 1ml of acetonitrile, filter before high-performance liquid chromatography detection. The specific methods are as follows.

Automatic Sample Purification-Concentration Apparatus | RayKol Group SPEVA 08N |

Solid Phase Extraction Column | Benzopyrene(a)Pyrene molecularly imprinted column: 500 mg/6mL |

Activation | Dichloromethane, n-Hexane |

Rinse | n-Hexane |

Elution | Dichloromethane |

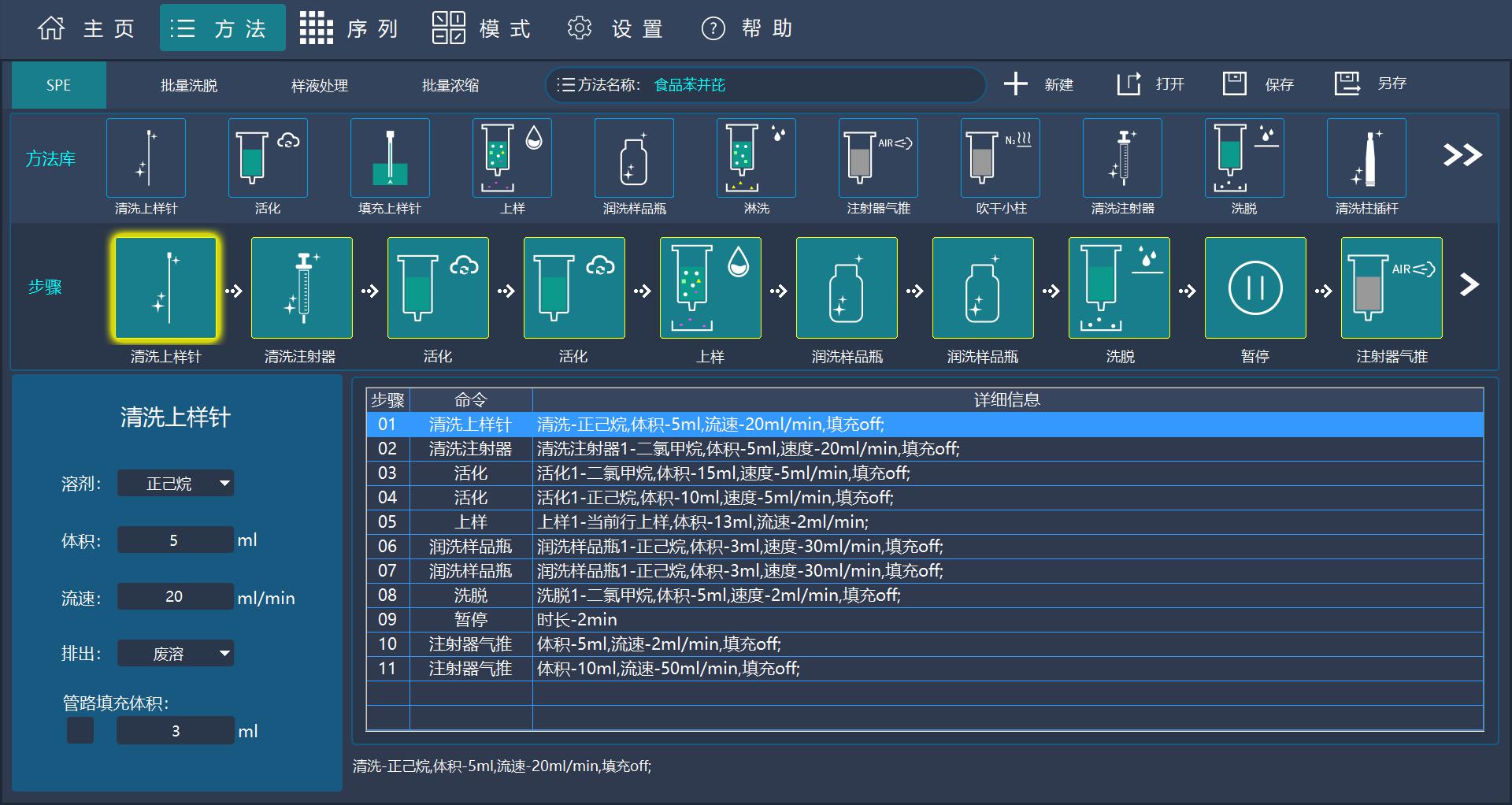

Figure 1. SPEVA 08N Solid Phase Extraction Purification Method

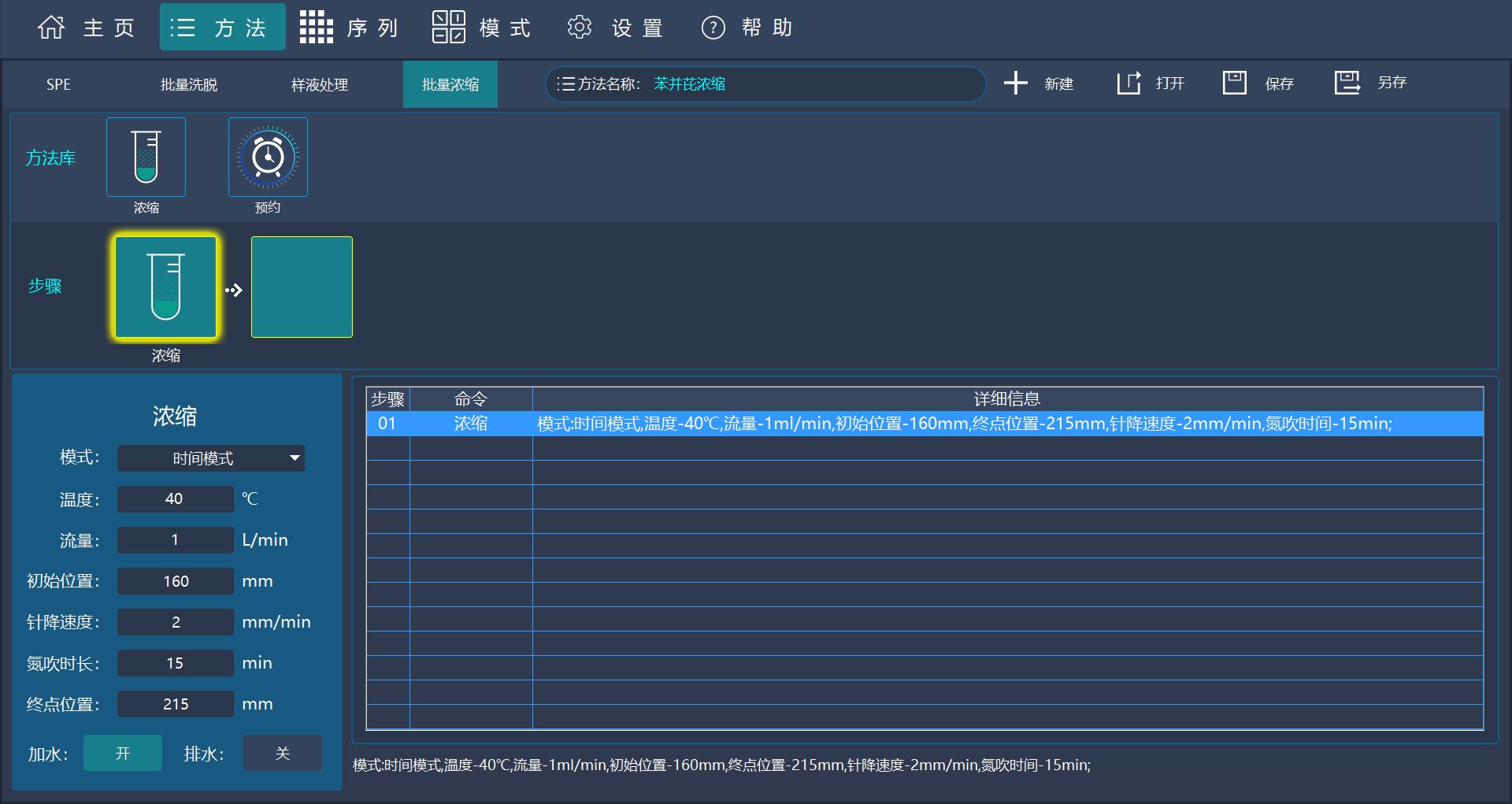

Figure 2. SPEVA 08N Concentration Method

| Column | Agilent Eclipse XDB-C18 (4.6×250 mm, 5.0 µm) |

| Column Temperature | 35 °C |

| Flow Rate | 1.0 mL/min |

| Injection Volume | 20 µL |

| Mobile Phase | Acetonitrile + Water = 88 + 12 |

| Fluorescence Detector | Excitation Wavelength 384 nm, Emission Wavelength 406 nm |

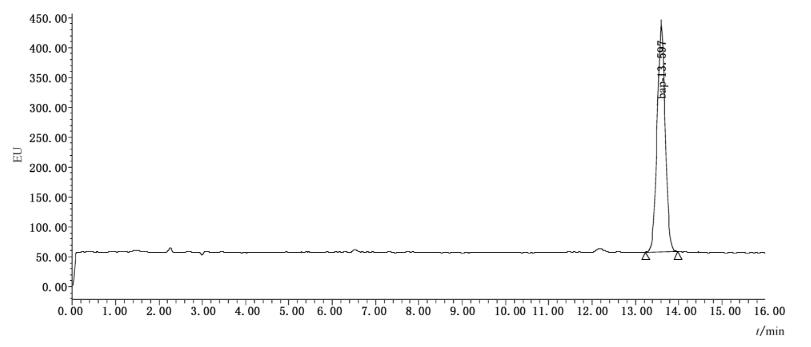

Figure 3. Benzo(a)pyrene liquid phase chromatogram (1.0 ng/mL)

In order to verify the recovery rate of this method, 1 g of oil sample was taken in this experiment, and benzo(a)pyrene standard (1.0 ng) was added for spike recovery verification (n=3). The data are shown in Table-2. The spike recovery rate is between 88%-93%, and the RSD value is controlled within 5%. This shows that this method can be well applied to the detection of benzo(a)pyrene in oils and fats.

Table-2. Spiked recovery rate and RSD value of benzo(a)pyrene in oil samples (n=3)

| Serial Number | Compound | Recovery Rate(%)Sample 1 | Recovery Rate(%)Sample 2 | Recovery Rate(%)Sample 3 | Average Recovery Rate% | RSD (%) |

| 1 | Benzo(a)pyrene | 88.4 | 89.8 | 92.4 | 90.2 | 2.3 |

This solution is easy to operate, integrates sample purification and concentration, has high recovery rate and good stability, and meets the quality control requirements of GB 5009.27-2016 "National Food Safety Standard Determination of Benzo(a)pyrene in Food".

The SPEVA08N fully automatic sample purification and concentrator of the RayKol combines high-throughput solid phase extraction with high-throughput nitrogen blowing, and can simultaneously perform 8-channel sample purification and concentration, support automatic identification of sample rack/collection rack/column rack/column plug rod, nitrogen blowing concentration comes with channel infrared constant volume, compatible with conventional SPE column mode, large volume loading mode, gun tip loading mode and membrane extraction mode, one machine with multiple uses, truly providing help for batch pre-treatment.